Schiedam, August 23, 2023 – Ammonia, a versatile chemical with applications ranging from fertilizers to chemical products, has gained significant attention due to its potential in the renewable energy sector, as a green energy carrier of hydrogen. Proton Ventures, since its inception in 2001, is setting new standards in ammonia storage & handling by employing cutting-edge technologies and adhering to stringent safety protocols.

Ammonia State Transitions: Gas to Liquid

At ambient temperatures, ammonia exists as a gas. However, by cooling it down to approximately -33°C, it transforms into a liquid. This phase change allows for the storage of larger quantities of ammonia in a the same volume, enhancing its efficiency as a storage medium.

Storage Infrastructure and Standards

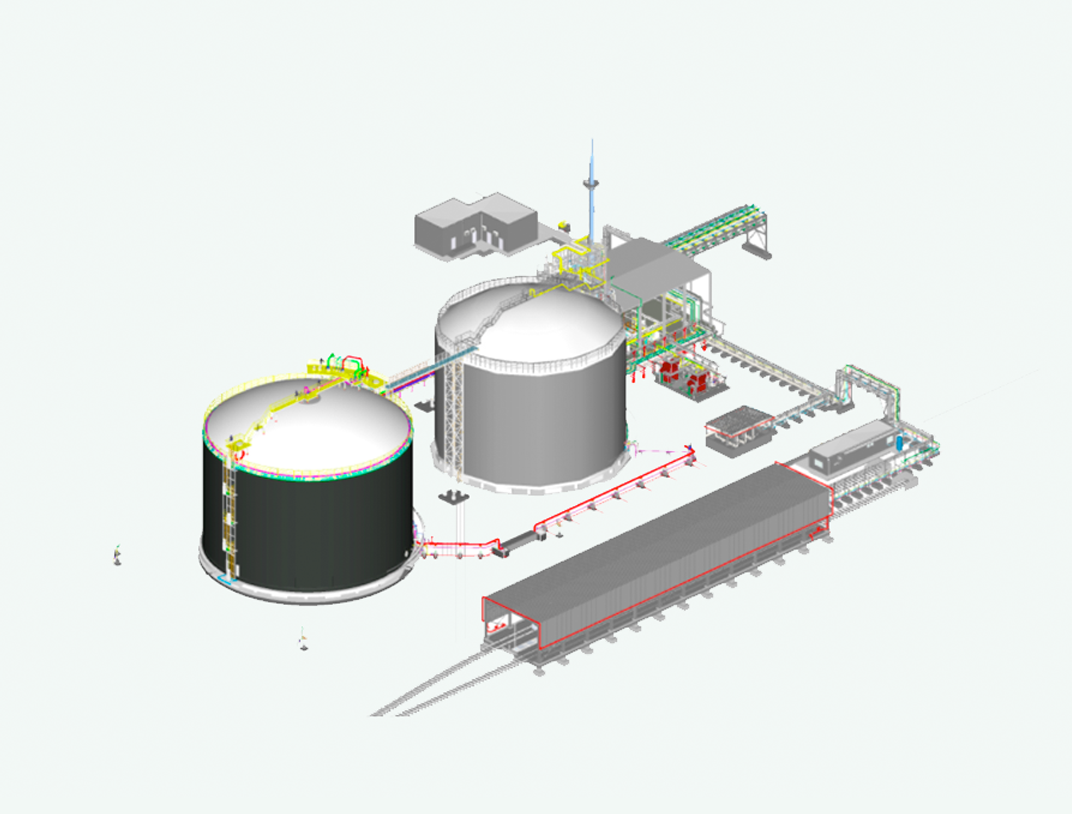

Ammonia storage demands rigorous safety measures and structural integrity. Storage tanks are constructed following internationally recognized codes such as EN14620, API620, and API625, depending on regional regulations. Proton Ventures adheres to these standards to ensure the highest level of safety for both employees and the surrounding environment.

The Dutch PGS-12 guideline is also implemented, reflecting Proton’s commitment to up-to-date design and operational practices. Material selection is crucial in withstanding stress corrosion cracking, a critical concern in atmospheric ammonia tanks. Low-temperature carbon steel is chosen for its resilience in this challenging environment.

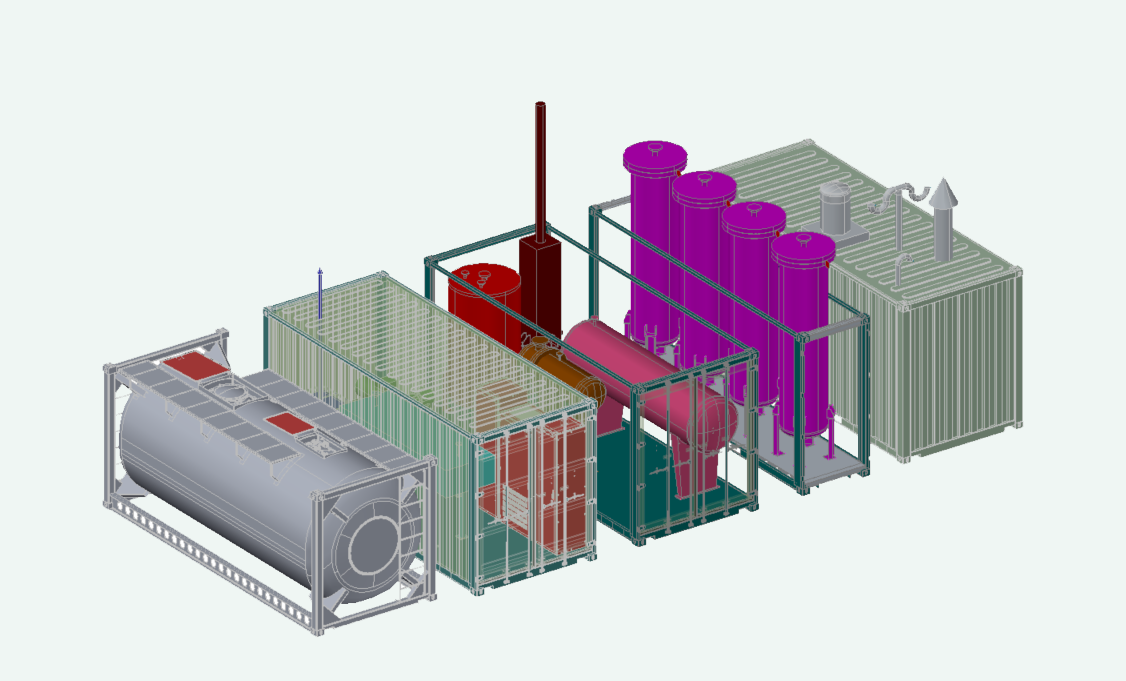

Proton Ventures’ Innovative Designs

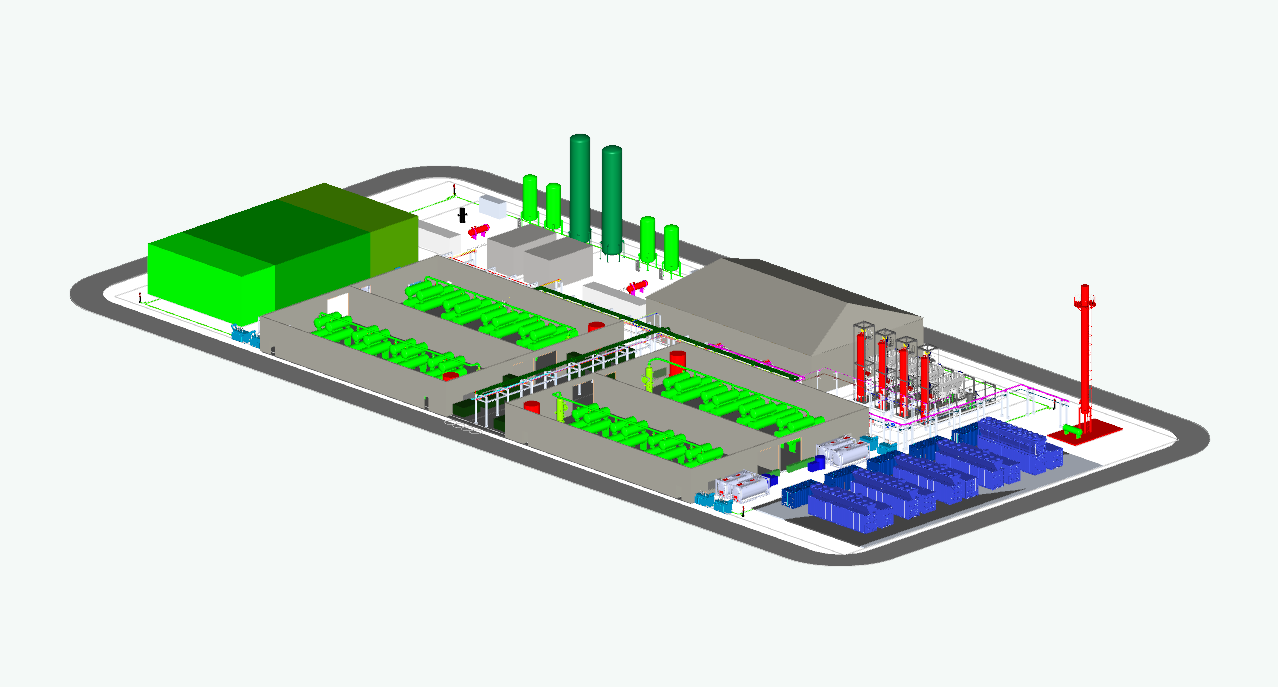

Proton Ventures’ terminals stand out due to their state-of-the-art design features that prioritize safety, efficiency, and environmental responsibility:

Full Containment and Suspended Roof

The utilization of low-temperature carbon steel tanks with a suspended roof design ensures enhanced safety and maximised storage capacity.

Insulation Excellence

The integration of external insulation on the outer steel wall ensures swift installation, prolonged inspect ability, and efficient temperature control.

Integrated Infrastructure

Our terminals incorporate a combination of flare systems, interconnecting bridges, and staircases to optimize capital expenditure, spatial utilization, and operational simplicity.

External Pumps

The implementation of external pumps streamlines maintenance, reduces downtime, and provides the flexibility to choose from multiple vendors.

Inherently Safe Valve Design

The introduction of a specialized main discharge/bottom valve enhances safety and minimizes operational risks.

Eco-Conscious Flaring

Intermittent flaring eliminates the need for a permanent flare, thus conserving natural gas and propane resources.

Towards Zero Emissions

Proton Ventures is exploring the possibility of designing zero-emission, zero-waste terminals, which could eliminate the necessity of using flares and result in valuable byproducts like aqueous ammonia.

Optimized Refrigeration

The refrigeration system’s innovative design focuses on high efficiency and reduced operational expenses.

Smart Pump Technology

Frequency-driven ammonia pumps ensure optimal efficiency and streamlined operations.

Safety and Expertise

One of Proton Ventures’ standout features is its specialized in-house team, proficient in procurement inspection, construction supervision, commissioning, start-up procedures, and operator training for ammonia storage terminals. Proton’s leadership in critical safety design and startup elements ensures the highest levels of safety and operational efficiency.

In conclusion, Proton Ventures is redefining ammonia storage with its innovative designs and unwavering commitment to safety, efficiency, and sustainability. As the world transitions towards greener energy solutions, Proton Ventures plays a pivotal role in ensuring the safe and efficient storage of ammonia, a vital component in the renewable energy landscape.