Schiedam, June 26, 2023 – Ammonia is increasingly considered as zero-carbon fuel and hydrogen carrier in a decarbonized energy and food landscape. As ammonia will become more abundant as an energy vector, its use as hydrogen carrier is set to increase. Ammonia cracker facilities for hydrogen production are currently considered in various northern European ports, such as Rotterdam and Wilhelmshaven.

Ammonia cracking for large-scale sustainable hydrogen production

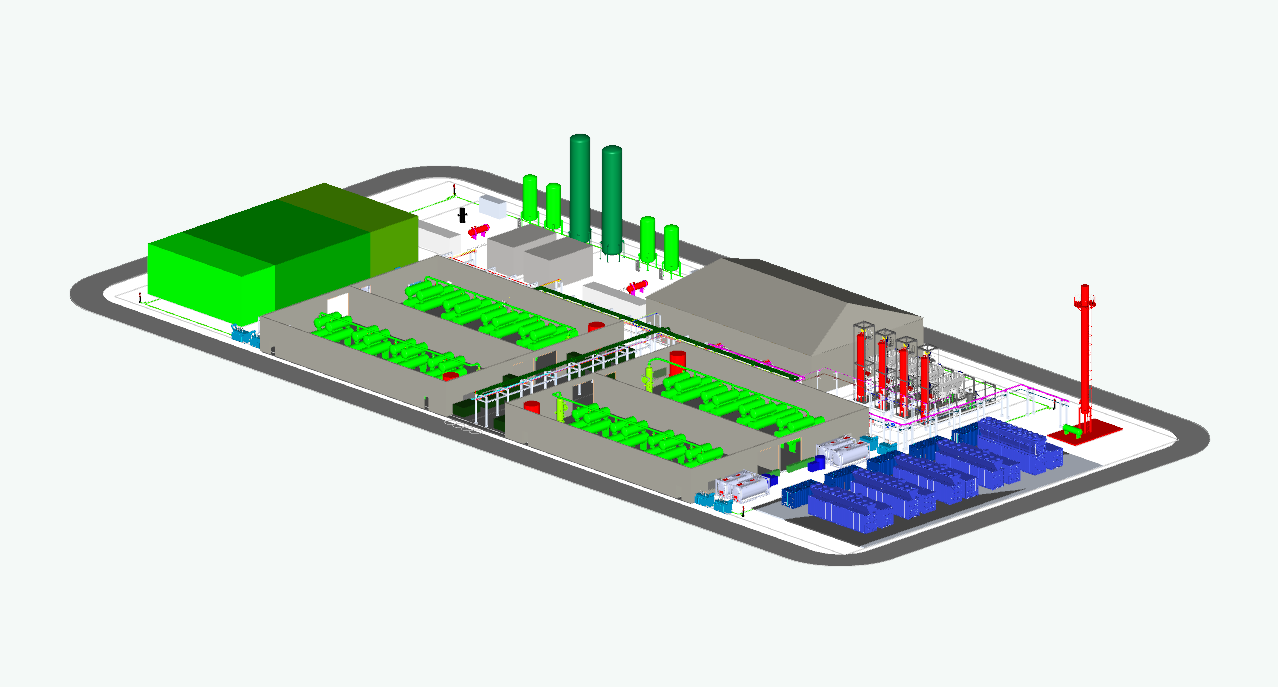

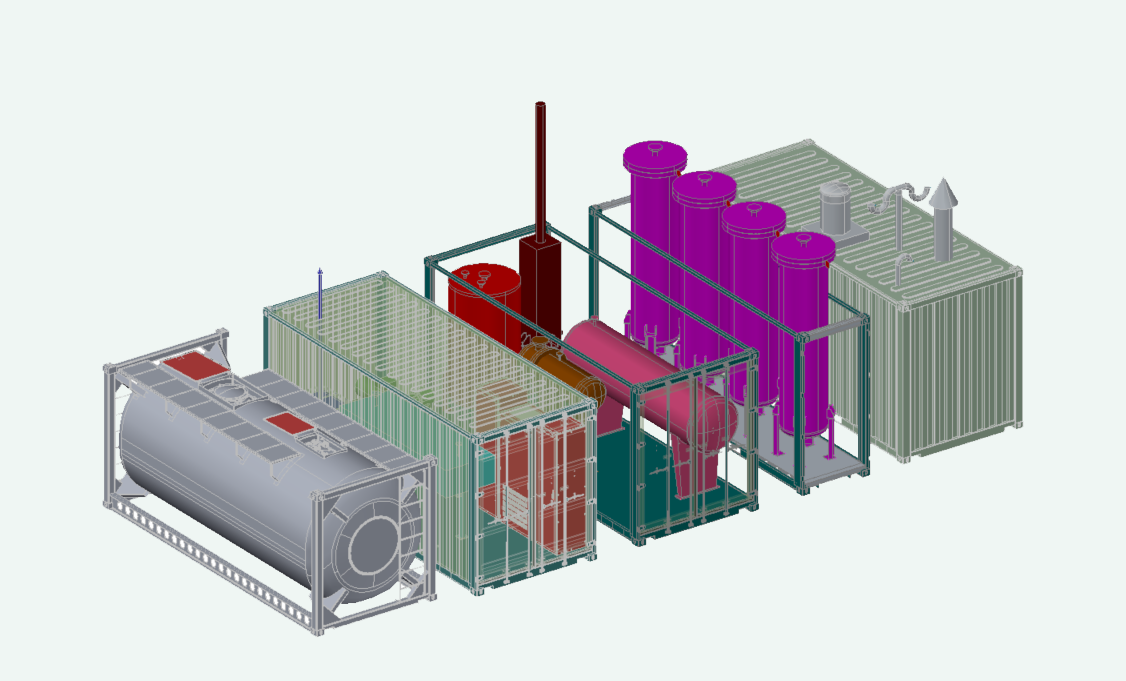

Proton Ventures has performed various studies on ammonia cracking for clients, and remains active within various research consortia. Such centralized ammonia cracker solutions for pure hydrogen production are functionally very similar to natural gas processing plants for hydrogen production. Alternatively, decentralized ammonia cracker solutions are currently developed, which do not always require full conversion and purification of the hydrogen, thereby improving the energy efficiency of the system and the cost.

To consolidate the solutions for ammonia cracking, we currently operating a high pressure ammonia cracking testing facility at the high-pressure laboratory at the University of Twente, the Netherlands. This is critical to validate the operational performance under industrially relevant conditions, while also allowing to test novel cracker concepts.

The next aim is to build a commercial pilot for ammonia cracking, which is an essential intermediate step for the industry to move toward world-scale hydrogen production facilities. A pilot plant is necessary, as performance in terms of ammonia feedstock utilization is key for the cost of produced hydrogen. The ammonia feedstock cost can account for over 90% of the total levelized cost of hydrogen from ammonia cracking. Thus, ensuring minimal ammonia feedstock utilization is paramount. At Proton Ventures, efficient process integrations in the developed processes allow for the lowest cost of hydrogen.

Ammonia storage & handling

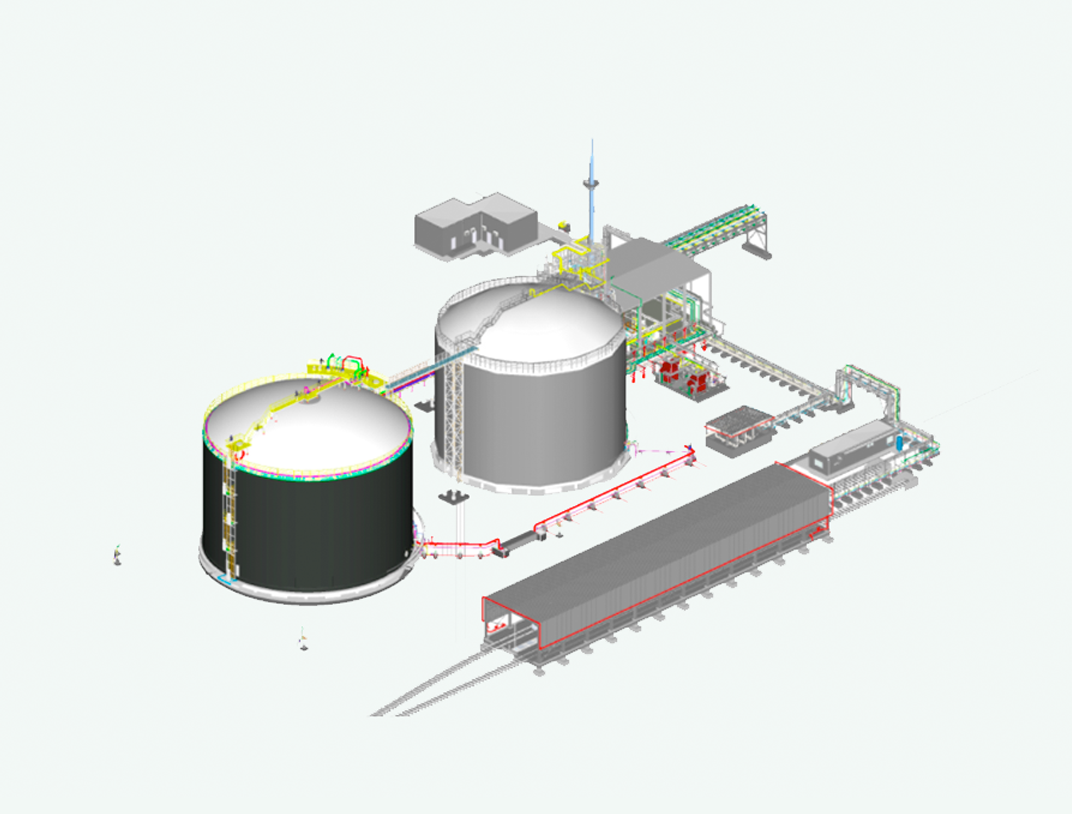

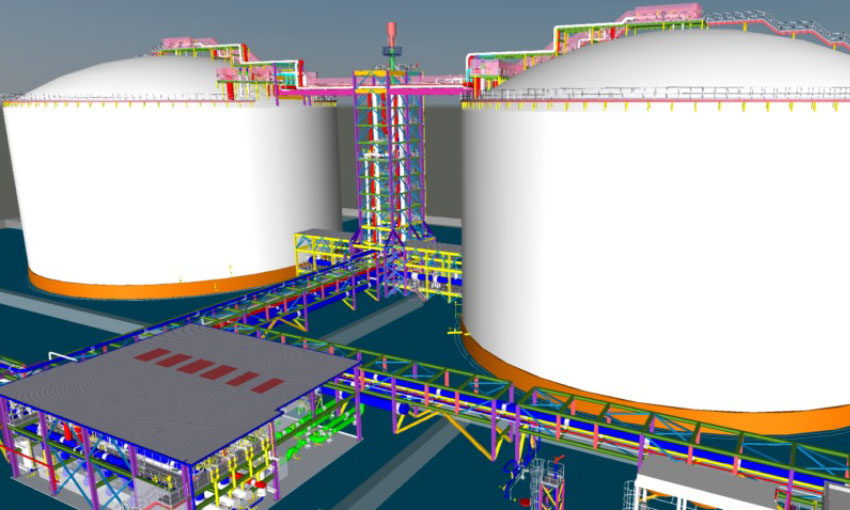

Every ammonia cracker needs ammonia storage & handling. Some of the largest projects executed by Proton Ventures are its refrigerated storage tanks in Estonia (BCT & Eurochem) and Bulgaria (Agropolychim), which are among the largest operating ammonia storage tanks in Europe. For example, the tanks in Estonia each have a capacity for 30 kilotonnes of refrigerated ammonia at -33°C. The tanks are double containment storage tanks complying with modern safety standards. The facilities in Estonia also consist of railcar loading and unloading systems, a marine loading arm facility, and four UAN tanks of 20 kilotonnes each. Full containment storage tanks can also be realized with Proton Ventures.

The global trade of ammonia is set to expand over the coming decade, as the use of ammonia as shipping fuel, as stationary fuel, and as hydrogen carrier is taking off. In light of these developments, Proton Ventures and consortium partners have been awarded a turnkey contract by OCP Group for two refrigerated ammonia storage tanks in Jorf Lasfar, Morocco. Also, Proton Ventures is currently investigating the revamping of two storage tanks operated by Vesta Terminals in Vlissingen, The Netherlands.

Proton Ventures complies with state-of-the-art requirements for new ammonia storage tanks, even when these are located in desert areas with temperatures sometimes measured in excess of 50°C. Recently, a FEED+ engineering package was completed for a new ammonia export terminal in the United Arab Emirates. Intermittent flaring and an interconnecting bridge between the two storage tanks with a combined staircase optimizes the capital investment, spatial utilization and simplicity. Furthermore, the refrigeration system design is optimized for hot climate operations and a low operational cost.

Project development for large-scale green ammonia production

Large-scale ammonia crackers also require large-scale green ammonia production. This is most economical in locations with optimal solar PV and wind electricity. These renewables are coupled with electrolysis for hydrogen production, air separation for nitrogen purification, and a Haber-Bosch plant for ammonia production.

Proton Ventures is active within the TransHydrogen Alliance (THA), which aims to produce ammonia in areas with abundant solar and wind resources, such as Brazil and Morocco, with subsequent transport and cracking of ammonia to hydrogen in Rotterdam, the Netherlands. Herein, the aim is to produce ammonia at world-scale, e.g. producing up to several millions of metric tonnes per annum. The benefit of the TransHydrogen Alliance is that production and utilization are coupled, allowing to ensure supply, while keeping the overall system cost low.

In February 2023, Casa dos Ventos and Comerc Eficiência, an energy efficiency company of the Comerc Energia Group, signed a partnership with the TransHydrogen Alliance. The purpose of the agreement is to enable the export of green ammonia produced in the Industrial and Port Complex of Pecém (CIPP), in Ceará. The plant is to be built on a 60-hectare site with a capacity of up to 2.4 GW of electrolysis, producing 960 tons of hydrogen per day, and with all phases implemented, will enable the production of 2.2 million tons of ammonia per year. The parties signed a Memorandum of Understanding to jointly develop a viable partnership targeting production of the first phase for export to Europe through the Port of Rotterdam, in the Netherlands in the year 2026.